What Is...??

Definitions

CAD-Cut

CAD-Cut is actually two words, well, an acronym and a word. CAD stands for Computer Aided Design. And as you guessed, CAD-Cut stands for Computer Aided Design Cut.

The cutting machine looks very much like an ink jet plotter or very wide format printer that can print on paper that is 24 inches, 30 inches, 54 inches and even more, wide. However, instead of a print head or pens in the plotter head, there is a very small, very sharp knife. That knife is raised and lowered and moved around the material that is to be cut, all under computer control. The result is that the material gets cut according to the computer instructions usually from a graphics program of one sort or another, such as a Sign Cutting software program or a Graphics Design program, along with the Cutter Driver software.

Your local sign shop usually has one or more of these machines on hand to produce vinyl signs. The same machine is utilized in the garment industry to create the cut Heat Transfer Vinyl and CAD-Cut Twill that is seen on sports teams uniforms.

Direct Digital Print

Direct Digital Print is the method of utilizing a special hardware printer, connected to a computer, that can print graphics, photographs, and text, directly onto a cloth garment. This is much like a printer that is designed to print on photographic paper. (But in this case the print heads and the "inks" are special to the garment print industry.) The print design is usually driven out of a commercial graphics design program.

This is not a new technique. This was first explored in France, many years ago. But the garment industry has not adopted this method until recently. The reasons for the late adoption were:

- High Production Costs and slow product output

- Print Technology was Experimental

- The print machines occupied large floor space, room size

- Dyes used in the process were not easily available

- Permanency of print was not there

- Printing on dark color garments was not possible

Today, all of that has been overcome. In fact, in 2005, alone, there were many manufacturers that introduced Direct-To-Garment printing systems. And even a less number of manufacturers produced machines able to print white designs on black or dark garments.

How permanent are the prints? As good as or even better than most silk screen prints. The prints may outlast the life of the shirt.

Will Direct Digital Printing replace screen printing? Not in our opinion. It can supplement the silk screen industry, by providing the low volume garment printing that is prohibitively expensive for silk screeners and their clients.

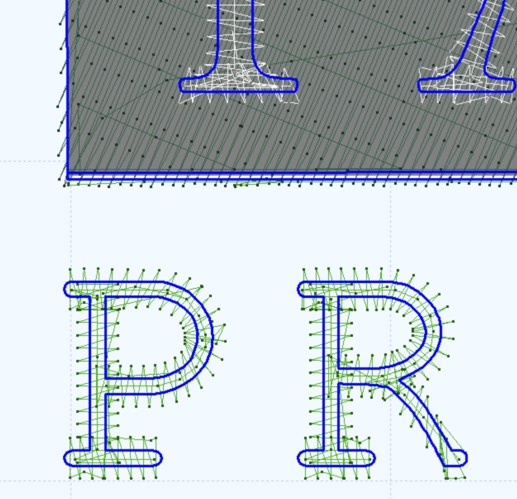

Digitize

Digitizing is the art of converting a graphic and/or text

design into a language that most embroidery machines can utilize to sew

that same graphic onto a garment.

Todays embroidery machines, whether for the home or for the largest multi-head industrial machines, require a set of instructions that tell the machine where to move the garment for the next stitch to be inserted and when to insert that stitch. Sounds simple and easy. But did you know that a simple embroidery design that is placed above a pocket, such as a company logo and name may involve as many as several thousand stitches? And the embroidery machine has to be instructed on how and where to place each and every stitch.

Digitizing is the method of converting a design into a series of stitch instructions and sequences for the embroidery machine.

Silk Screen Films

If you have a film camera, then this will sound a little familiar. A film is a translucent or transparent substrate on which a photo image is produced.

OK. What a silk screen film is, is a positive print of what you want to have screen printed. This is the second step in producing silk screened products, such as tee shirts. The first being the graphics design.

The graphics design is color separated. That is, the colors are broken up into their basic primary combinations. This is usually in the four colors of Cyan, Magenta, Yellow and Black. There are six, eight and even higher, color separation color counts. but the basic four are CMYK (K is the black color).

For Silk Screen Films, the color separations are "Positive", i.e.: unlike a film camera, the film is not a negative. It looks like a print on film and not on photo paper, but always in tones of black for each of the primary colors. In other words, the amount of Cyan ink is expressed in shades of grey-to-black on the positive Cyan film sheet. The same goes for each of the other primary colors. The silk screen house uses these films to expose onto a sensitized pre-stretched screen. The screens are then chemically processed and dried, much like a photograph. At this stage, the design resides on one or more screens, ready for the screen printing machine.

Most screens will not last forever. Even these have to be replaced. However, the film positives are utilized only at the time of the screen exposure and development, so the films should last a life time, with proper handling and storage.